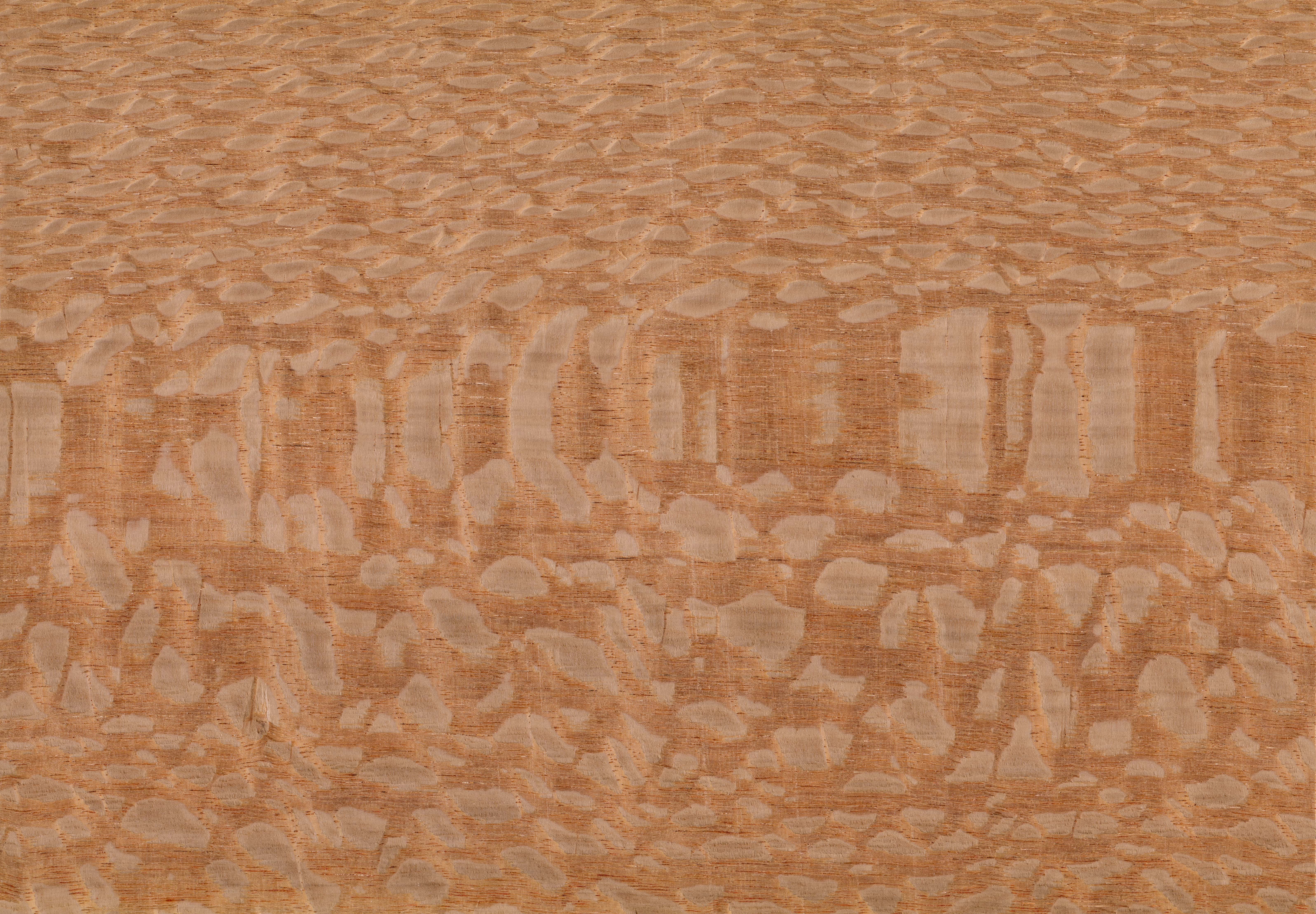

Lacewood, also known as silky oak or Australian lacewood (although it’s not a true oak), is a distinctive wood with a lace-like pattern on its surface. It is commonly used for various woodworking and decorative applications due to its unique appearance and workability.

Lacewood Is A Versatile Wood With Many Uses

Here are some typical uses for lacewood:

- Fine Furniture: Lacewood is often used to create high-quality furniture, especially for veneers on tabletops, cabinet fronts, and drawer faces. Its striking figure adds an elegant touch to pieces.

- Cabinetry: It is utilized for crafting cabinets, both as a solid wood and as veneer. Its appearance can turn an ordinary cabinet into a statement piece.

- Interior Trim: Lacewood can be employed for moldings, paneling, and other interior trim elements, adding a touch of sophistication to rooms.

- Musical Instruments: Some musical instrument makers use lacewood for the backs and sides of acoustic guitars, ukuleles, and other stringed instruments, where its unique look complements the aesthetics.

- Box Making: Lacewood is popular for crafting decorative boxes, jewelry boxes, and humidors due to its eye-catching grain pattern.

- Turning: Woodturners appreciate lacewood for its ease of turning and its ability to create stunning bowls, vases, and other turned objects.

- Architectural Detailing: In architectural applications, lacewood is sometimes used for ornamental details like inlays, decorative panels, and moldings.

- Art and Crafts: Artists and craftsmen may use lacewood in mixed-media projects, marquetry, or as an accent in various art forms.

- Decorative Panels: Lacewood veneer is employed in decorative wall panels, doors, and cabinetry to enhance the visual appeal of interiors.

It’s important to note that lacewood is relatively soft and not as durable as some other hardwoods, so it may not be the best choice for high-impact or outdoor applications. However, its exquisite appearance makes it a sought-after wood for adding a touch of elegance to various projects.

Properties That Make Lacewood Useful In Woodworking

Here are some additional details about the working properties of lacewood to explain why it can be considered a popular choice for woodworking:

- Machining – Lacewood machines smoothly, taking a nice polish. It can be cut, carved, turned, sanded, and shaped easily with hand or power tools.

- Nailing/Screwing – The tight grain means it holds nails, screws and dowels well without splitting once seasoned properly. Predrilling is recommended.

- Gluing – Lacewood glues smoothly and creates strong bonds. Common woodworking glues like Titebond work well. Clamping should fully compress the joint.

- Sanding – It sands smoothly through all grits up to a high polish. Start coarser and work up to finer papers to accentuate the graining.

- Finishing – Lacewood readily accepts stains, dyes, oils and polyurethanes. Multiple thin coats are best to let the finish penetrate and protect.

- Turning – As mentioned, it’s a favorite of turners due to its figure and the smooth cuts made on the lathe. Hollowing requires steadiness.

- Denting/Scratching – While durable once finished, lacewood’s softness means it can dent or scratch more easily than harder woods. Handle with care.

- Shrinkage – Its movement with changes in humidity is moderate. Allow for expansion/contraction in large furniture panels or flooring. Proper drying reduces issues.

Additional Uses And Facts Regarding Lacewood

Here are some additional interesting facts about lacewood:

- Medical Uses – Some indigenous groups historically used lacewood medicinally. Parts of the plant were made into poultices or teas to treat infections, stomach issues, and skin disorders.

- Spiritual Symbolism – In parts of Africa and Asia, lacewood’s intricate veining was thought to represent the interconnectedness of life. Carvings were used in spiritual rituals and ceremonies.

- Shellac Finishing – Applying a shellac finish, then sanding it back lightly, allows the lacewood grain to really “sing”. The resin fills pores to make patterns bolder.

- Acoustic Properties – The tight, elastic grain contributes to lacewood’s resonance when used for musical instruments. It translates vibration into rich, balanced tone.

- Blending With Other Woods – Marquetry and parquetry artists blend lacewood strips with boldly figured woods like bubinga or purpleheart for dramatic high-contrast designs.

- Australian Variety – “Grey lacewood” from Australia has subtly mottled patterns in shades of gray, brown and greenish blue highly valued by woodworkers Down Under.

- “Spalting” Effect – Decay fungi sometimes colonize lacewood, causing beautiful blue or gray streaks within the grain reminiscent of spalted maple. This is prized by artists.

- Endangered Species – Some species of lacewood like Filipino Calamian lacewood have been listed as threatened due to illegal logging of mature trees for their valuable wood.

Tips To Deal With The Softness Of Lacewood

Here are some tips for preventing dents and scratches when working with lacewood:

- Use a backing board when planing, sawing or sanding to prevent the softer face from denting against the table or machine plates.

- Apply soft pads or self-adhesive protective films to surfaces that wood will contact on tools, clamps, workbenches, etc. to cushion it.

- Face grain edges with thin hardwood strips like maple to protect them during assembly, finishing and handling.

- Carefully sand and finish all surfaces, including edges, to build up protective layers that resist dents and scratches.

- Consider pre-finishing high-risk surfaces like tabletop edges before assembly to armor them early in the project.

- Use featherboards or push sticks when machining to avoid pressing directly on the wood with hands.

- Handle parts carefully when staining, sanding or installing hardware to avoid any digs or gouges. Use rags underneath.

- Pad or wrap exposed edges that may get bumped with felt, soft vinyl or self-adhesive edge banding for protection.

- Apply exterior polyurethane or durable oils to furniture surfaces that will see high wear or abrasion to reinforce the wood.

- Store and transport finished pieces with protective wrapping or crates to avoid any damage in transit or storage.

Lacewood Alternatives To Consider

There are a few other wood species that have grain patterns similar to lacewood that might be substituted for it, if you have trouble sourcing enough for your project:

- Flamewood – Also known as curly maple, flamewood has tight, wavy grain lines that resemble flames or ribbons. The patterns can be as intricate as lacewood.

- Tigerwood – Features dramatic dark stripes on a lighter background, very similar to a tiger’s coat. The stripes of tigerwood tend to be thicker than lacewood’s finer lines.

- Bubinga – Exhibits interlocking waves or ribbons of darker reddish brown color against a lighter background. Sometimes called African rosewood.

- Birdseye maple – Known for its small circular patterns that resemble bird’s eyes. Not as linear as lacewood but still a highly figured wood.

- Snakewood – Thin dark wavy lines combined with lighter toned areas give it the look of snakeskin. Grain is more subtle than lacewood.

- Flamed koa – The Hawaiian wood koa sometimes develops curly, interlocking flame-like patterns very close to lacewood’s graining.

- Claro walnut – When quartersawn, claro walnut can show fine linear rays reminiscent of lacewood’s lacy veining.

So in terms of intricate linear patterned grain, flamed maple, tigerwood and bubinga would perhaps be the closest analogs to lacewood’s one-of-a-kind appearance.

Final Thoughts

Lacewood is a decorative (moderately) hardwood that is prized for its beautiful grain patterns. Here are some common uses for lacewood:

- Furniture: Lacewood makes very attractive furniture pieces like dining tables, coffee tables, cabinets, bookshelves, etc. due to its unique veining.

- Accent Walls: The subtle patterns of lacewood look great as wall accents in dining rooms, living rooms, or home offices. It adds visual interest to a wall.

- Flooring: Some people use lacewood to floor rooms where they want an eye-catching wood grain underfoot. It holds up well with a finish.

- Musical Instruments: The acoustic qualities of lacewood make it suitable for use in guitars, ukuleles, and other stringed instruments. The wood enhances the tone.

- Turned Items: Woodturners enjoy working with lacewood to create bowls, vases, candlesticks and other lathe-turned objects that highlight its intricate grain.

- Artisan Crafts: Lacewood lends itself to carvings, intarsia, marquetry and other decorative woodworking techniques where the beauty of the natural patterns is the focal point.

So in summary, lacewood is typically used for applications where displaying its unique grain structure is a design priority, like furniture, wall accents, flooring and turned objects. Its looks make it a prized decorative hardwood.

Recent Posts

Wood, a ubiquitous natural material, has been a staple in construction, art, and various applications for centuries. However, there is a common misconception about whether wood can melt. In this...

Building a treehouse is a childhood dream for many, and the choice of wood plays a pivotal role in bringing that dream to life. The right wood not only ensures the structural integrity and longevity...